Comments

- No comments found

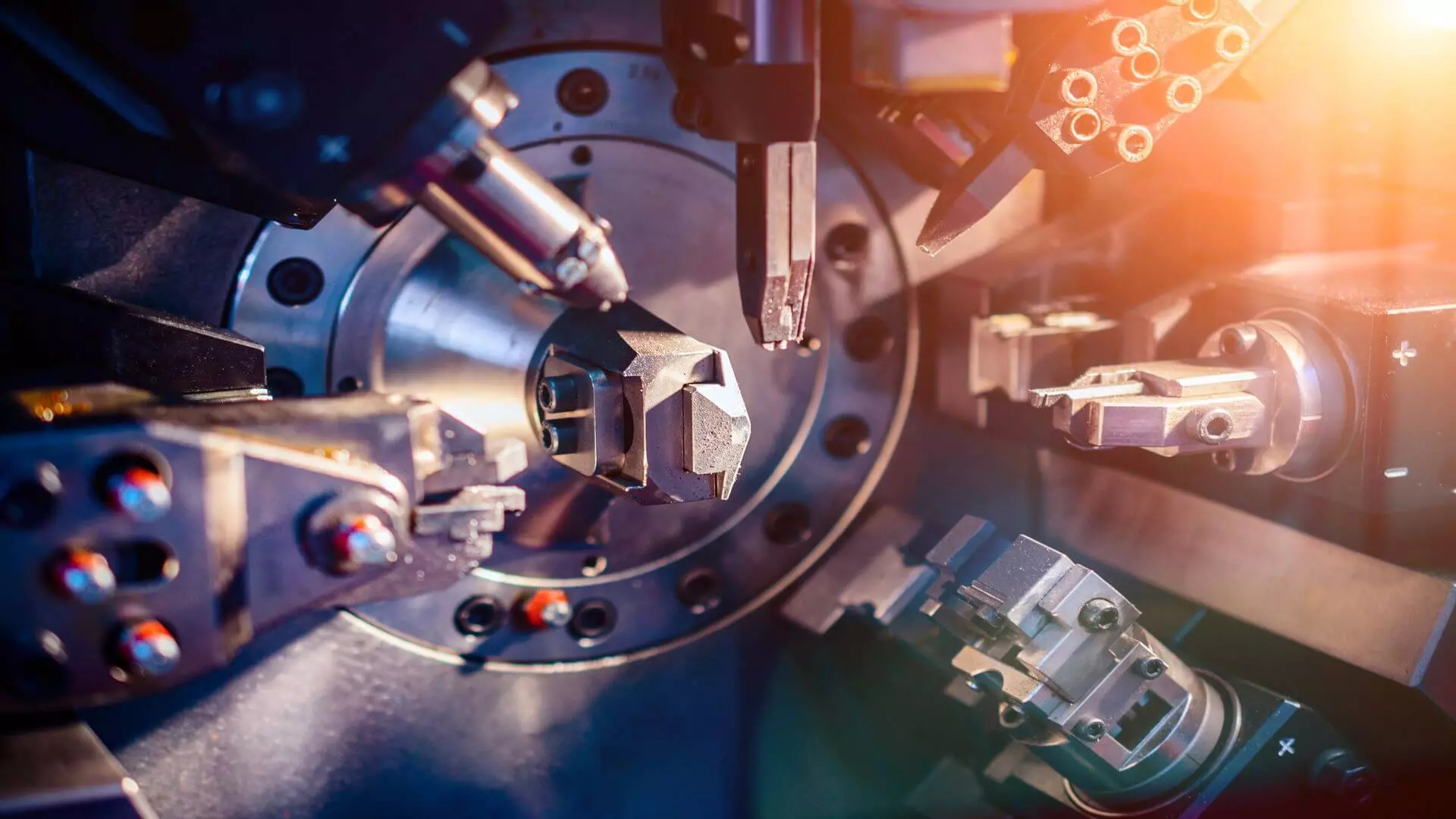

With the advancement of technology through the years, machining has become a critical part of building the physical world.

Without machining and manufacturing, components building cars, electronics, and medical devices won’t exist today. To ensure top-notch build quality, machinists use different types of equipment to achieve precise fabrication. Case in point: a workholding tool.

Choosing An Effective Workholding Solution

The goal of any manufacturing process is to produce accurate products consistently. Workholding is one of the most overlooked aspects of manufacturing, but it’s a quintessential part of productivity and consistency. Essentially, workholding devices are responsible for locating and holding a workpiece in a fixed, secure position while manufacturing operations take place.

Using the right workholding solutions is paramount to streamlining your production. When looking for a workholding solution, you should look for one that can optimize simultaneous machining of different parts with very minimal variation. For a more in-depth search, consider these four tips when looking for a workholding solution for your production line:

Regardless if you own the most sought-out or expensive workholding device, it won’t work if compatibility and stability is an issue. Since the purpose of the workholding solution is to hold a piece, then it should be compatible with the parts you’re working with. Therefore, size, dimensions, and shape are important parameters to help you find the right workholding solution for it.

Here are some sample situations to guide you:

If the part is too small, there should be multiple parts palletized to hold it.

If the part is too large, consider adding custom pieces and upgrades to cater to its size.

If the part is too thin, a solution that can distribute clamp force in a large area is preferred to allow high torque pressure.

If the piece has a rounded shape, devices like V-blocks, lathe chucks, or collet chucks are ideal to hold the diameter.

If the piece is prismatic or has flat sides, modern drill press vises are enough.

Picking an inappropriate device for your workhold piece may impact your production negatively, especially the precision and accuracy of each product.

Identifying a material’s physical and mechanical properties is a key step in the material selection process of manufacturing. Knowing how the material reacts to stress, heat, and other environmental factors can help predict the final product, particularly in metal fabrication. Aside from shape and size, the condition of the parts you’re working with should come into play as well.

Workpieces can come in a raw, casted, or partially finished form. For instance, raw materials are yet to be machined and require tolerance in size, so the workholding solutions should be able to handle variable sizes. Also, think about the part’s tendency to deform or bend under mechanical stress, as you’ll need a workholding solution that can spread the forces on the workpiece.

A workholding system is often divided into two categories: mechanical or hydraulic workholding.

As the name implies, a mechanical workholding system needs manual work to clamp or secure each piece into the system. The mechanical option is a more traditional method, making its initial costs lower than a hydraulic one. Also, its components are much easier to find as it’s been a market commodity. Since you’ll need to place pieces manually, there’s a higher chance of lack of accuracy, precision, and consistency with the manufacturing outcome.

Meanwhile, hydraulic workholding solutions utilize pneumatic systems to position, secure, clamp, and release workpieces. You’ll often see components like pumps, valves, and cylinders in this workholding system. When making more challenging products sensitive to accuracy, a hydraulic system is a better option. However, finding a replacement part is difficult when there’s an issue within the system, so there’s no other choice but to replace the entire unit.

The manufacturing industry has had a fair share of its technological breakthroughs. These advancements have paved the way to higher production rates and better-quality products while maintaining cost-efficiency. With plenty of options in the market today, you can never go wrong with an automated workholding system.

Fusing automation and workholding offers a competitive advantage than going the conventional route. You’ll get to enjoy these endless advantages of introducing automation to your system:

More advanced and adaptable workholding techniques

Increased repeatability and accuracy

Improved machining capabilities

Has potential to work with non-traditional materials

Evolving strategies when managing complex parts

With the increasing demands of businesses and consumers, manufacturers should constantly create products of higher quality. To achieve these expectations, choosing the right tools and equipment to aid their operations should be of paramount importance, like the workholding solutions responsible for fabricating smaller parts that make up a final product. Using the tips above, make sure to find the right workholding solutions tailored to the needs of your business.

Leave your comments

Post comment as a guest