Comments

- No comments found

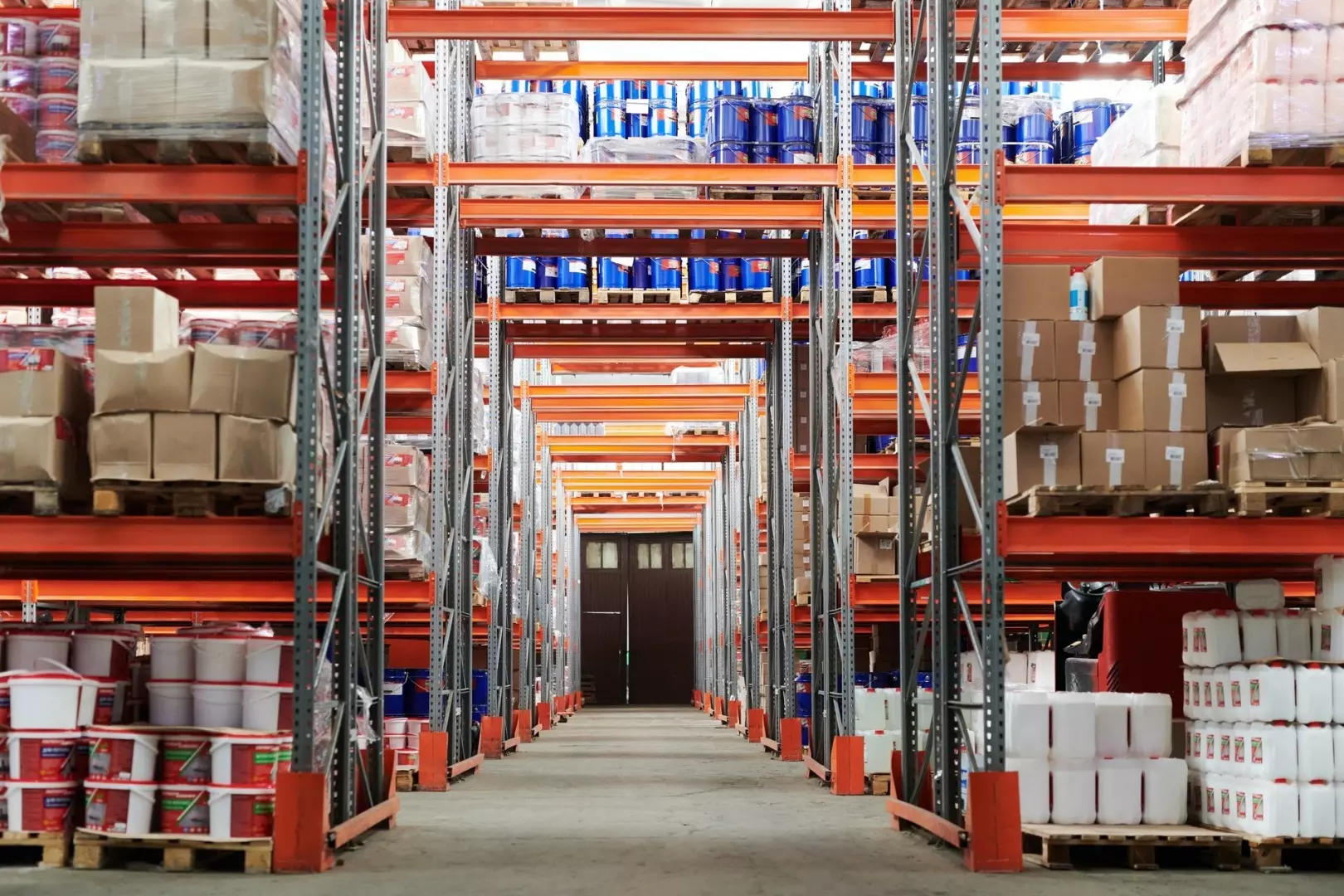

Palletizers are used to move the product from the production line to the final destination.

They can be as small as a single pallet, or as large as 300. Palletizers can be used for transporting goods in warehouses and distribution centers, as well as moving small batches of products on short runs. Palletizers can also reduce labor costs by eliminating manual lifting and heavy-lifting tasks.

The need for palletizers is driven by the desire to reduce labor costs and increase productivity. Palletizers are often used in warehouses, where it is important to be able to move boxes quickly and efficiently. Companies that must complete a large number of pallet moves per day will find a palletizer is an essential piece of equipment. Check out the advantages of using a palletizer below.

Palletizers operate with fewer labor requirements and can be programmed to make repetitive moves quickly. With a palletizer machine, employees won't have to repeatedly lift and stack boxes as they are moved around the facility. This can help reduce on-the-job injuries that may occur with manual lifting. Because the operator only has to load the product onto a platform that will automatically move up and down, it reduces the need for heavy lifting and manual labor.

They allow companies to move multiple boxes at one time. For example, instead of lifting several small boxes onto a forklift, several large boxes can be loaded onto the machine before being lifted. This not only reduces physical effort but will also provide time savings throughout the day when many pallets must be moved in a short period of time.

Palletizers move the product more quickly than traditional manual operations. This helps to increase productivity and prevent backlogs. Since different types of boxes need to be moved around warehouses, it is difficult for employees to keep up with demand and reduce stacking time. With a palletizer, one machine can handle multiple products at one time, quickly transferring large quantities of goods without interruption or delay.

When goods are moved from Point A to Point B using the row-forming machine, they move faster and more products are stacked in no time.

Palletizers reduce the need for manual lifting, which greatly reduces potential injuries related to handling products manually. Injuries can include strains, sprains, and other injuries that will make it difficult for employees to complete their tasks. In addition, they do not have sharp edges that may cut or injure the hands of employees who handle them frequently. This reduces potential liability issues that could occur from worker injuries.

If employees must lift heavy loads repeatedly throughout their shift, they may experience muscle aches or repetitive motion injuries that will slow them down and require time off. The addition of a palletizer eliminates manual labor, keeping your production line moving at maximum speed.

Since a person is no longer required to lift boxes multiple times throughout the day, there will be a decrease in human error related to heavy lifting. Most of the time when a product arrives at its destination damaged, it's because an employee accidentally dropped it while loading or unloading items, and this could cause serious problems with customer satisfaction.

Automating the process using a palletizing solution eliminates these risks and ensures all products arrive safely to their destination.

During peak season, companies often experience an increase in demand that requires more goods to be processed and shipped out quickly. With a palletizer, you can adapt to higher workloads easily by increasing the speed of your machine.

They are extremely flexible machines that have the ability to operate at maximum speed, so they can accommodate increased demands. They can also be programmed to run overnight during off-peak hours, so there is no interruption with daily operations or backlogs when products are needed most.

It's important to incorporate a row-forming solution into your warehouse operations during peak seasons to reduce order backlogs and meet customer needs on time. By adding a row-forming machine, you can increase warehouse productivity and maintain a smooth workflow.

Heavy-lifting tasks such as stacking piles of boxes or carton-cutting are eliminated with a palletizer. Damage to products or packaging is more likely, and expensive when an employee must lift heavy boxes multiple times throughout the day. With a row-forming machine, many boxes can be stacked on top of each other at once, instead of requiring several rounds of single trips up and down stairs or into storage areas.

Palletizers improve order accuracy by automatically storing and stacking boxes using robotic arms that quickly move across the rows with maximum speed.

A person is not required to operate the equipment; therefore, employees do not need special training or education before they can start working. The automated systems make it easy for managers and supervisors to train warehouse employees how to use their new machines efficiently in only a few hours.

Palletizers are designed with safety features that prevent injuries when boxes slide off the machine when stacking too high.

With the addition of a row-forming machine, you can reduce labor expenses by eliminating human handling and improve order accuracy, so no products are misplaced or delayed.

Products can be stored and stacked more efficiently when they're in rows and columns on pallets. They can also be stored closer together with less wasted space when employees don't need to access the floor, when products are delivered or picked up, for example.

Palletizers create uniform conditions that increase visibility by allowing managers to see all side-by-side goods clearly without having to move any boxes around. There's no need to push carts through narrow aisles or navigate stacks of heavy boxes that could fall over at any second.

The automation solution helps ensure safety and increases warehouse productivity by increasing order accuracy and reducing time wastage due to human error. If you're ready to incorporate automated equipment into your warehouse operations, contact a palletizing equipment company today.

Leave your comments

Post comment as a guest