Comments

- No comments found

Decanter centrifuges play a crucial role in various industries, from wastewater treatment to the food and beverage industry.

Understanding how they work and their applications is essential for optimizing processes and achieving efficient separation of liquids and solids. In this article, we will delve into the workings of decanter centrifuges and explore their wide range of applications.

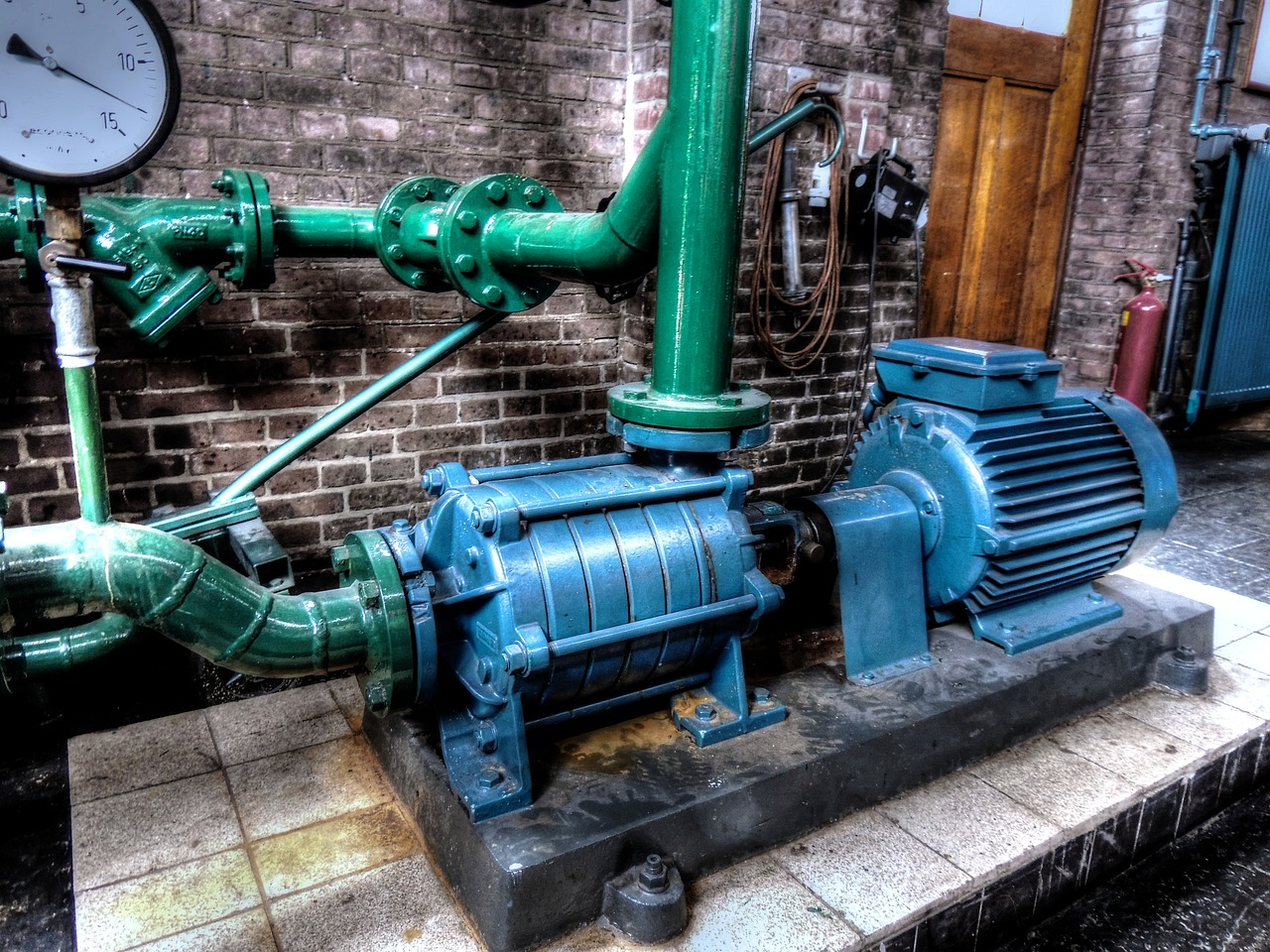

Decanter centrifuges work by using centrifugal forces to separate solids from one or two liquid phases continuously. The main application of a decanter centrifuge is to remove large amounts of solids from liquids. The process involves feeding the slurry, a mixture of solids and liquids, into a rotating bowl that has a cylindrical/conical shape. The slurry inside also rotates as the bowl rotates at a pre-set speed. The centrifugal force generated causes the heavier solids to settle on the bowl's inner wall, while the clarified liquid overflows from the other end. A rotating conveyor, often referred to as a screw conveyor, continuously moves the settled solids towards the discharge end, ensuring a continuous separation process. The efficiency and effectiveness of decanter centrifuges make them widely used in industries such as wastewater treatment, mining, food and beverage production, and oil and gas refining.

There are two main types of decanter centrifuges: horizontal and vertical. Horizontal decanter centrifuges are widely used due to their versatility and efficiency. They are commonly employed in wastewater treatment, mining, and chemical processing industries. Vertical decanter centrifuges, on the other hand, are specifically designed for applications where the liquid needs to be discharged from the bottom of the bowl.

Horizontal decanter centrifuges offer several advantages. They provide high separation efficiency, allowing for the removal of fine solids from liquids. They are also capable of handling large volumes of feed material, making them suitable for high-throughput operations. Horizontal decanter centrifuges find applications in wastewater treatment, where they play a crucial role in the removal of solids and the clarification of effluent.

Vertical decanter centrifuges are often used in industries such as pharmaceuticals and biotechnology. They offer advantages such as compact design and ease of installation. Their ability to discharge liquid from the bottom allows for efficient separation of materials with different densities. Vertical decanter centrifuges are commonly employed in applications where continuous separation is required, such as in the production of pharmaceuticals and chemicals.

Decanter centrifuges find diverse applications across various industries. In wastewater treatment, they are used for the removal of solids and the clarification of effluent. By separating solids from liquid, decanter centrifuges help in the treatment of sewage and industrial wastewater, ensuring compliance with environmental regulations.

The food and beverage industry also benefits from the use of decanter centrifuges. These machines aid in the separation of liquids and solids, facilitating the production of beverages, oils, and fats. Decanter centrifuges are commonly utilized in the extraction of olive oil, where they ensure the separation of oil from the olive paste, resulting in high-quality products.

In the oil and gas industry, decanter centrifuges play a crucial role in the clarification of crude oil and the separation of solids from drilling muds. By efficiently removing solids and impurities, decanter centrifuges contribute to the production of clean and high-quality oil. They also help in maintaining drilling fluid properties, enhancing drilling operations.

Decanter centrifuges offer several advantages that make them popular in various industries. Firstly, they provide high separation efficiency, ensuring the effective removal of solids from liquids. Secondly, decanter centrifuges operate continuously, allowing for uninterrupted processing. This continuous operation leads to high throughput, making them suitable for large-scale applications. Additionally, decanter centrifuges have low maintenance requirements, reducing downtime and increasing productivity.

However, decanter centrifuges also have some limitations. Cost considerations may arise due to the initial investment required for purchasing and installing these machines. Moreover, decanter centrifuges may have limitations in specific applications due to material compatibility issues. It is crucial to carefully consider these aspects when choosing a decanter centrifuge for a particular application.

Several factors should be considered when selecting decanter centrifuges for specific applications. Capacity and throughput requirements are vital considerations, ensuring that the machine can handle the desired volume of feed material. Material characteristics, such as viscosity and particle size distribution, should also be taken into account to ensure optimal performance. Additionally, operational parameters and control systems should be evaluated to ensure efficient operation and ease of use.

Decanter centrifuges are versatile machines that play a crucial role in various industries, including wastewater treatment, food and beverage production, and oil and gas refining. By utilizing the principles of gravitational separation, these machines effectively separate liquids and solids, enabling efficient processing and improving product quality.

Understanding how decanter centrifuges work and their diverse applications is essential for optimizing processes and making informed decisions when selecting the right equipment. Factors such as capacity, material characteristics, and operational parameters should be considered to ensure optimal performance.

With their numerous advantages, including high separation efficiency and continuous operation, decanter centrifuges have become indispensable tools in industries where liquid-solid separation is critical. By harnessing the power of decanter centrifuges, businesses can achieve cost savings, environmental sustainability, and improved product quality.

Leave your comments

Post comment as a guest