Comments

- No comments found

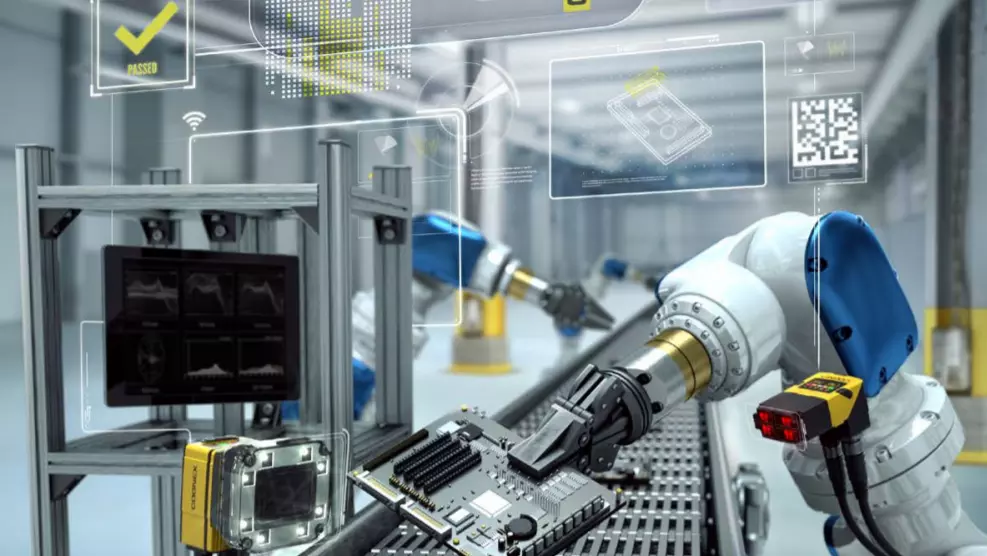

Deep learning provides advanced analytics tools for processing and analysing manufacturing data.

Employing deep learning in manufacturing enables companies to reduce costs incurred on hardware and software, optimize manufacturing machines, and accurately predict sales statistics based on previous company records.

Manufacturing departments in companies are always looking for ways to minimize the production cost and time, while improving the quality and quantity of the goods manufactured. Companies have, so far, have hired expert hardware personnel for routine assembly line checks, operations managers for optimum supply chain management (SCM), and market analysts to predict sales and growth. These methods, though effective, are not the most favorable ones to influence a company’s manufacturing statistics. This is where deep learning in manufacturing comes into the picture.

Here’s how deep learning in manufacturing is changing the face of the age-old industry:

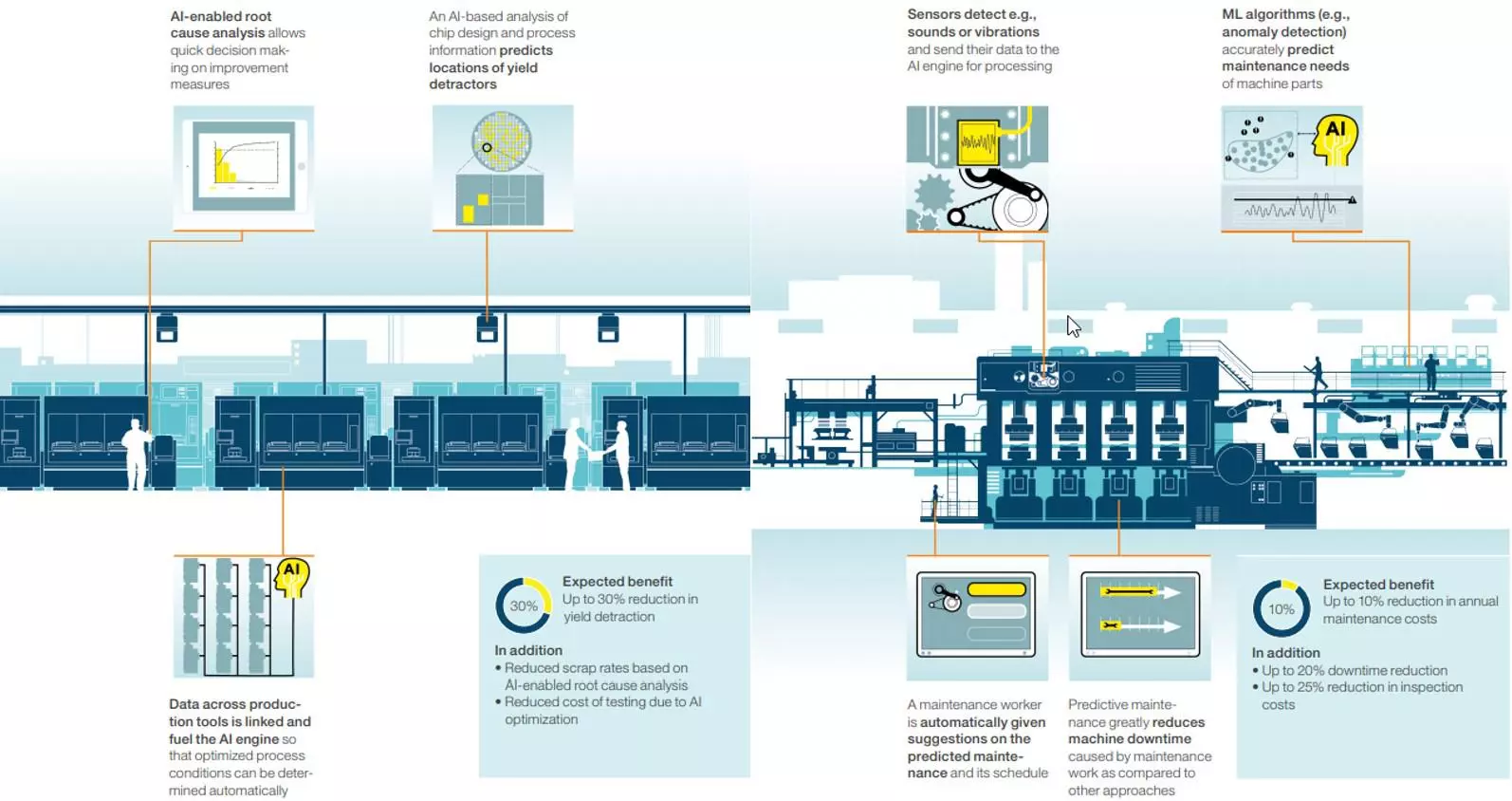

Deep learning algorithms can completely refine the production process. By employing programs that can upgrade existing systems, track and report errors, and allow for experiments with design, deep learning enables companies to establish robust systems, which can maximize the yield in a shorter time and at reduced costs. For instance, semiconductor manufacturing companies integrated deep learning technology with their fabrication systems and observed a 30 % increase in the output. Deep learning algorithms can help with:

Deep learning approach makes comprehensive failure analysis, statistical process control, experimental research, and the development of upcoming products possible. The technology significantly reduces the time taken for testing and designing new prototypes and the duration for redesigning the existing models. AI computers running deep learning programs on such operations are expected to bring down machine downtime by 20% and inspection costs by 25%. The German conglomerate company, Siemens, has been employing neural networks to inspect its steel machinery for quality control.

Deep learning in simple terms is pattern recognition. Applying algorithms for pattern detection to massive datasets, like that of a company’s supply chain statistics, can yield better results as compared to running the datasets through manual expertise. Predictive analysis is used to forecast an increase or a decrease in the sales of a product. Neural networks with supervised learning techniques are used to study records of previous trades to form patterns that forecast errors, depict the unfavorable supply chain routes, and revise inventory and asset management. Anomaly detection methods can be deployed for tracing the supplied goods and for tracking the lost consignments. All these techniques help in optimizing manufacturing by considerably reducing the lost and last-mile delivery damages, which add to the company overheads.

With all the results generated by studying and analyzing the large sets of data, data learning algorithms are expected to predict sales accurately. Structured inverse prediction and clustering techniques are employed to develop a heuristic sales operation system that prioritizes the needs of the manufacturing sector, predicts future maintenance procedures, and determines the overall equipment effectiveness. All these possibilities of deep learning are exciting and seemingly easy to incorporate. However, there are many hurdles to overcome before a complete integration of deep learning into the legacy manufacturing units is undertaken. Looking at the rate at which the technology is currently growing, it can be said that very soon deep learning will impact businesses in a big way by revolutionizing the manufacturing industry.

Naveen is the Founder and CEO of Allerin, a software solutions provider that delivers innovative and agile solutions that enable to automate, inspire and impress. He is a seasoned professional with more than 20 years of experience, with extensive experience in customizing open source products for cost optimizations of large scale IT deployment. He is currently working on Internet of Things solutions with Big Data Analytics. Naveen completed his programming qualifications in various Indian institutes.

Leave your comments

Post comment as a guest