Comments

- No comments found

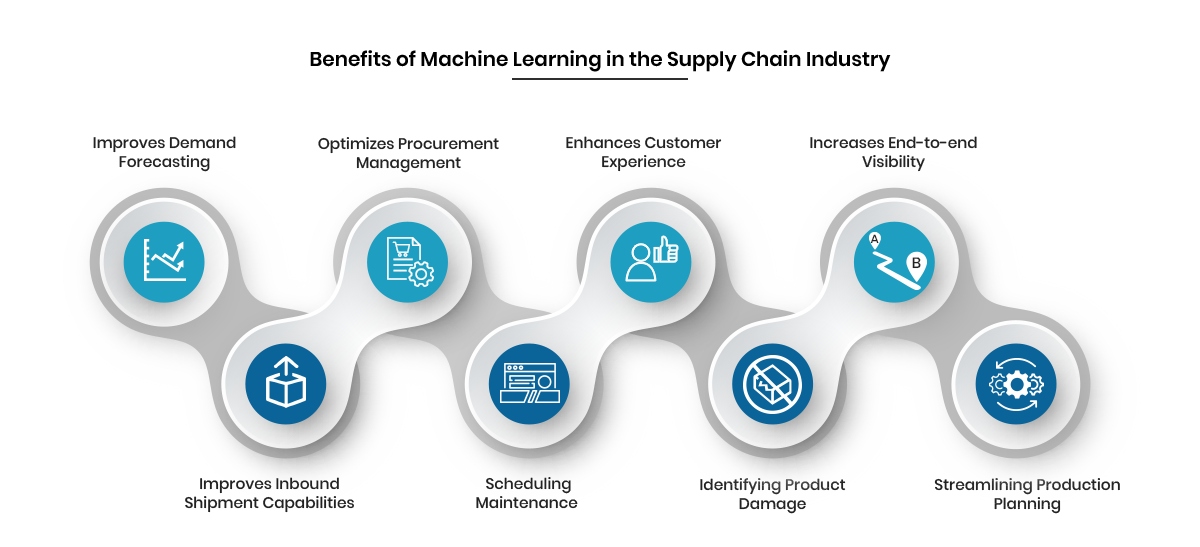

Machine learning can provide significant benefits including real-time demand forecasting, sustainable logistics, and advanced predictive analytics.

The logistics and supply chain industry is a complex network of various interconnected components that require meticulous planning, execution, and optimization to ensure smooth and efficient operations. The industry is constantly evolving, and with the advent of technology, new solutions are being developed to tackle traditional problems. Machine learning (ML) is one such technology that has the potential to revolutionize logistics and supply chain management.

Machine learning has the ability to analyze vast amounts of data, recognize patterns, and make predictions that humans may not be able to perceive. This capability of ML has caught the attention of logistics and supply chain managers who are looking for ways to improve operational efficiency, reduce costs, and enhance customer satisfaction. In this article, we will explore the benefits of machine learning in logistics and supply chain management and its potential to transform the industry.

Predictive maintenance is a proactive maintenance strategy that leverage machine learning algorithms to predict when a machine is likely to fail. By analyzing data from sensors and other sources, ML algorithms can detect patterns that indicate an impending failure. This enables logistics and supply chain managers to schedule maintenance before the machine breaks down, thereby minimizing downtime and reducing repair costs.

For example, DHL uses machine learning algorithms to predict maintenance requirements for its delivery trucks. By analyzing data from sensors installed in the trucks, the algorithms can identify potential issues and alert the maintenance team. This has resulted in a 10% reduction in maintenance costs and a 25% decrease in truck downtime.

Demand forecasting is critical for logistics and supply chain managers as it enables them to plan production, inventory, and transportation. Machine learning algorithms can analyze historical data and external factors such as weather, holidays, and economic trends to predict future demand accurately. This helps managers to optimize inventory levels, reduce stockouts, and minimize waste.

For example, Walmart rely on machine learning algorithms to forecast demand for its products. By analyzing sales data and other factors, the algorithms can predict demand with a high degree of accuracy. This enables Walmart to optimize inventory levels, reduce waste, and improve customer satisfaction.

Route optimization is a complex problem in logistics and supply chain management, and machine learning can help solve it. Machine learning algorithms can analyze data from various sources such as traffic patterns, weather conditions, and delivery schedules to determine the most efficient route for a delivery. This helps to reduce transportation costs, minimize delivery time, and improve customer satisfaction.

For example, UPS exploits an ML-based optimization engine called ORION to determine the most efficient delivery routes for its drivers. By analyzing data from various sources, ORION can optimize routes in real-time, resulting in a 100 million-mile reduction in annual driving distance and a savings of 10 million gallons of fuel.

Warehouse optimization is crucial for logistics and supply chain managers as it enables them to maximize the use of available space, reduce inventory costs, and improve order fulfillment. ML algorithms can analyze data from sensors, cameras, and other sources to optimize warehouse layout, inventory placement, and order picking processes.

For example, Amazon utilizes machine learning algorithms to optimize its warehouse operations. By analyzing data from sensors and cameras, the algorithms can optimize inventory placement and order picking processes. This has resulted in a 50% reduction in operating costs and a 60% increase in warehouse capacity.

The logistics and supply chain industry is undergoing a significant transformation with the advent of ML technology.

Machine learning can have a significant impact on logistics and supply chain management in the future.

Machine learning algorithms can analyze vast amounts of data, recognize patterns, and make predictions that can help logistics and supply chain managers to optimize operations, reduce costs, and enhance customer satisfaction. The use of machine learning in logistics and supply chain management is still in its early stages, and there is immense potential for further innovation and improvement.

Leave your comments

Post comment as a guest