Comments

- No comments found

"In the era of electric vehicles, one can either resist change or embrace innovation," as articulated by EV industry visionary and Tesla CEO Elon Musk.

This statement underscores the imperative of adapting to the rapidly evolving automotive landscape.

Accurate machining services play a pivotal role in shaping the performance, efficiency, and safety of electric vehicles. EVs are known for their high efficiency and torque, and precision components contribute to this by reducing energy loss, enhancing power delivery, and optimizing the overall driving experience. Moreover, they ensure that the various subsystems in the vehicle, such as the motor, transmission, and battery management system, work seamlessly together. This synergy minimizes energy wastage and maximizes the range of the vehicle.

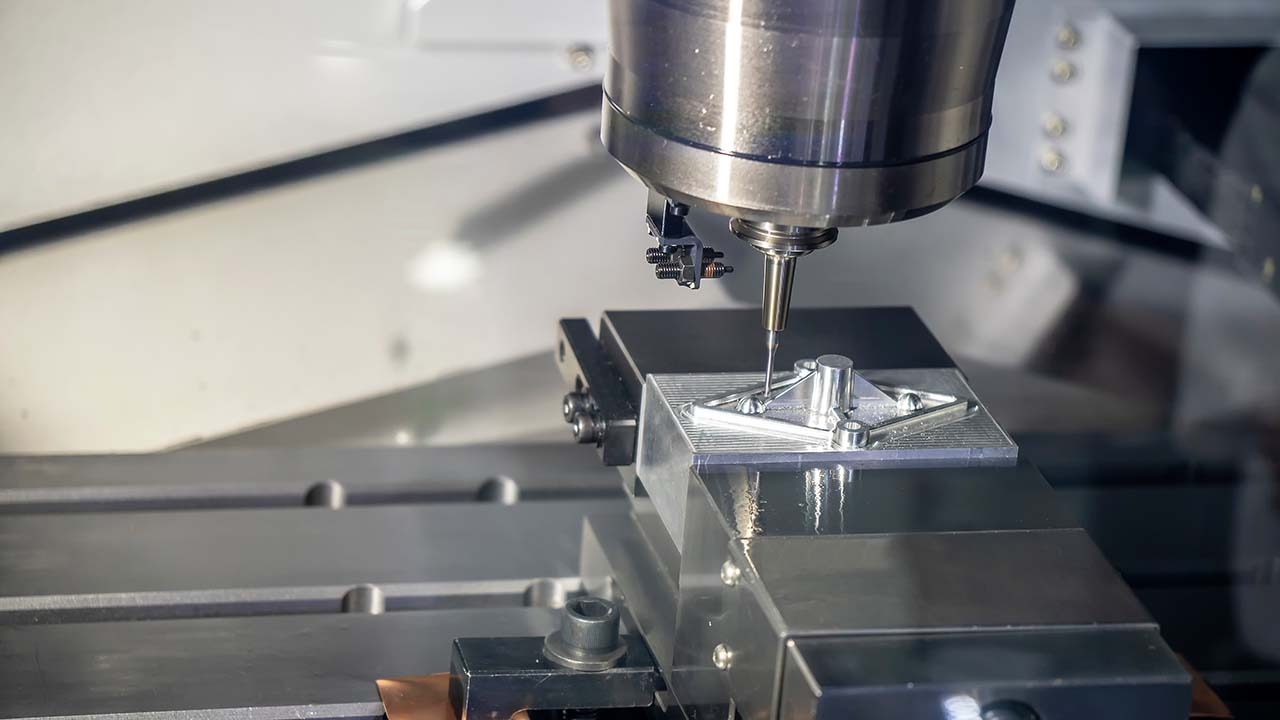

CNC machining plays a pivotal role in the manufacturing of precision components for electric vehicles (EVs) by enabling highly precise cutting, shaping, and finishing processes.

In the production of engine parts, CNC machines are utilized to create intricate components like cylinder heads and crankshafts, ensuring optimal combustion efficiency.

For transmission components, CNC technology guarantees precise gear tooth profiles and shafts, leading to smoother power transmission and lower energy loss during gear shifting.

In braking systems, CNC machining is indispensable for fabricating brake calipers, ensuring the exact tolerances necessary for reliable and consistent braking performance.

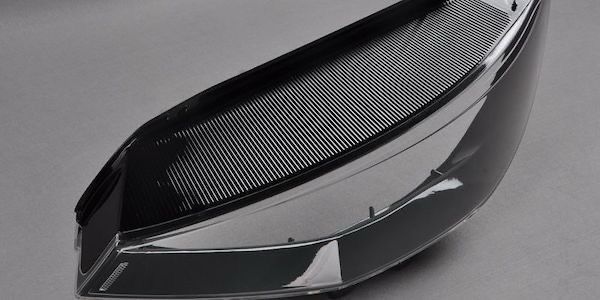

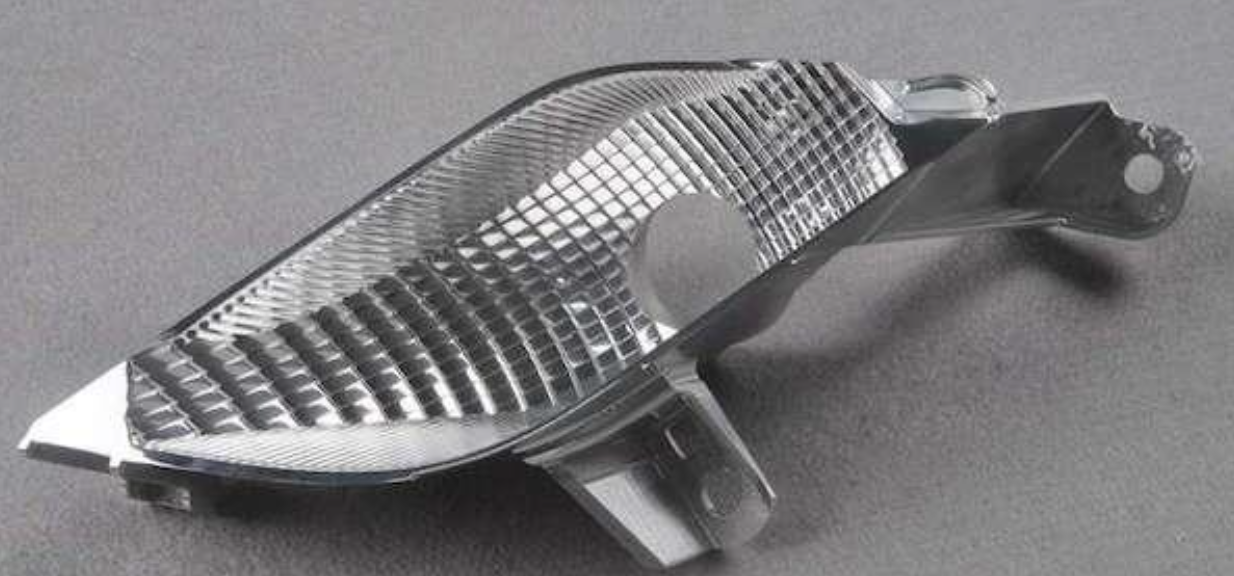

Furthermore, when it comes to body parts, CNC machines are employed to produce complex structural components with precise fits, enhancing both safety and aerodynamics.

CNC machining, with its computer-controlled precision, allows for the seamless creation of these critical EV components, contributing to their overall performance, efficiency, and safety.

1. Battery Enclosures: The battery is the heart of an electric vehicle, and its enclosure must be robust and protective. Precision CNC machining ensures that battery enclosures are manufactured with tight tolerances and can withstand external factors like impacts, temperature fluctuations, and vibrations.

2. Motor Parts: Electric motors require precision components for efficient operation. CNC machining is used to produce motor components, such as rotor and stator cores, with intricate designs that optimize power output and efficiency.

3. Electronic Connectors: EVs rely heavily on electronic systems. Precision connectors are crucial to ensure reliable communication and data transfer between various components. CNC machining guarantees the exacting specifications required for electronic connectors.

Manufacturing precision components for electric vehicles comes with its set of challenges. Maintaining tight tolerances and addressing design complexities are among the most prominent challenges. Electric vehicles demand a high level of precision due to their efficient powertrain systems, and any deviation can lead to energy losses and decreased performance.

Addressing design complexities is another challenge. EVs often feature complex and innovative designs to optimize aerodynamics and space efficiency. Rapid prototyping and manufacturing technology is vital in managing these complexities, as it can accurately reproduce intricate and unconventional designs, ensuring the highest level of efficiency.

Accurate machining services stand as a pivotal solution in the realm of precision component manufacturing for electric vehicles (EVs). As the automotive industry undergoes a rapid transition toward EVs, the importance of CNC machining cannot be overstated. This technology, through its computerized precision control, offers unparalleled advantages. It skillfully addresses the challenges associated with tight tolerances and complex designs, ensuring that every component aligns precisely with the specifications required for efficient electric vehicle systems.

The versatility of CNC machines further enhances their significance, as they can proficiently work with a wide array of materials, including aluminum, steel, and composite materials. This adaptability allows for the creation of components that are not only exceptionally precise but also durable and lightweight – a crucial combination in the development of efficient and high-performance electric vehicles.

Leave your comments

Post comment as a guest