Comments

- No comments found

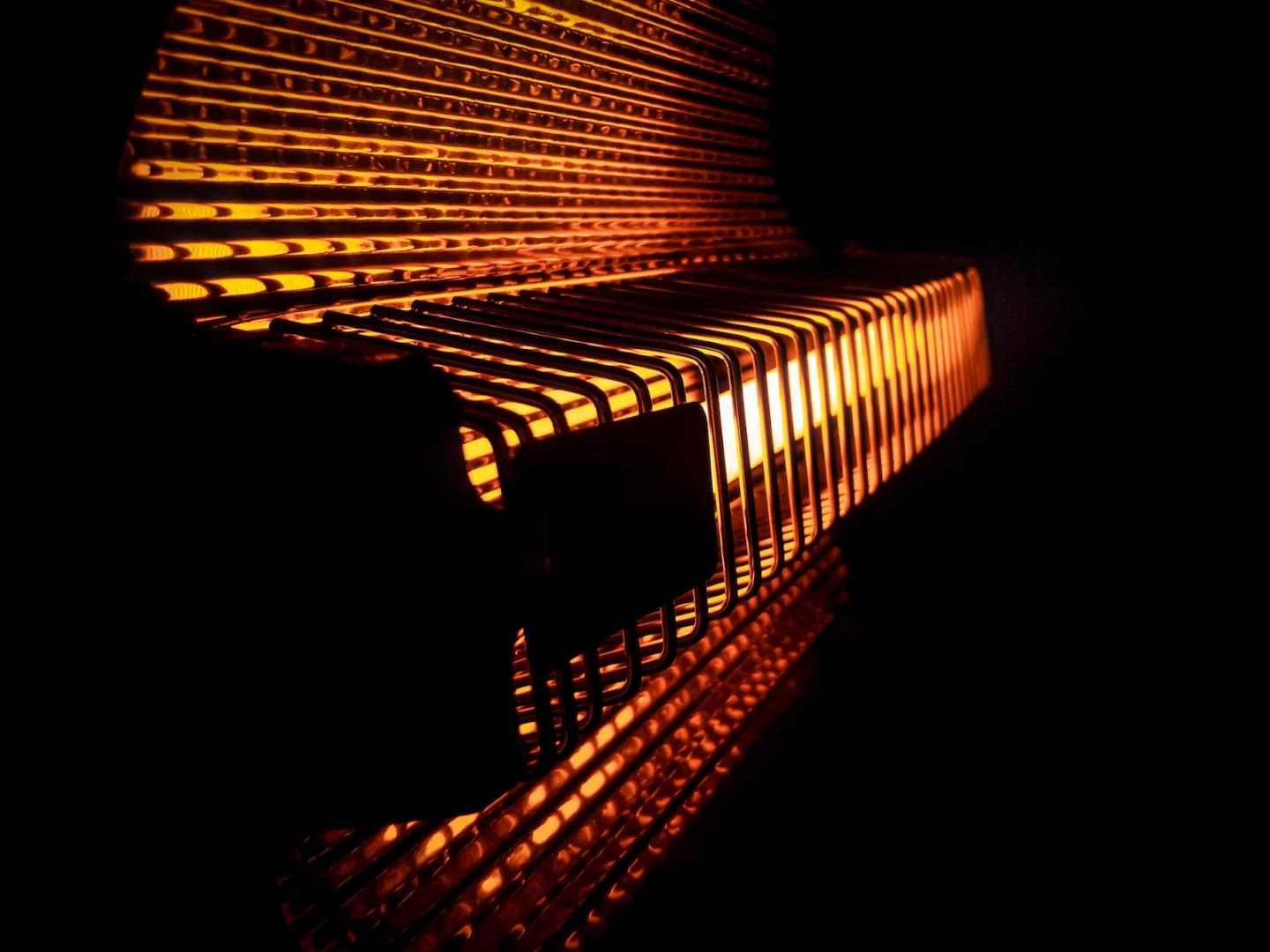

Industrial heaters play a pivotal role in numerous processing and manufacturing applications.

Their primary function is to transfer heat to substances under treatment, such as air, liquids, or gases. This happens in a controlled manner to initiate or accelerate certain processes. Industrial heaters come in a variety of types, each designed for specific applications and environments. Understanding the fundamental principles guiding their operation, their categories, and their uses in different industries is essential for making an informed decision when choosing a heating solution for your industrial processes. In this document, we are going to provide useful information about this crucial topic.

Industrial heaters are categorized into various types according to their design and application, including immersion heaters, band heaters, cartridge heaters, strip heaters, coil heaters, and tubular heaters. These heaters can be further classified into two broad categories: electric heaters and fuel-fired heaters. Furthermore, whether you choose to rent a heater from Cahill Heating Rentals or you decide to purchase one, it is crucial to understand the differences between these types and their functions. In addition, it is essential to consider factors such as energy efficiency, maintenance requirements, and safety when selecting the right type of industrial heater for your specific needs.

Industrial heaters can utilize different energy sources. Some run on electricity, while others are powered by propane, natural gas, or even solar energy. The choice of energy source depends on the availability, cost, and environmental impact. Electric heaters are more common in industries that require precise temperature control and operate in enclosed spaces. On the other hand, fuel-fired heaters are suitable for outdoor applications or large industrial settings where electricity may not be available. Moreover, fuel-fired heaters are more cost-effective in the long run, as they have lower operating costs compared to electric heaters.

The energy efficiency of an industrial heater is an important consideration. High-efficiency heaters can significantly reduce energy costs over time. Electric heaters are known for their high efficiency, as they convert almost all the energy into heat. However, this also means that they can be expensive to operate, especially in industries with heavy heating demands. On the other hand, fuel-fired heaters may have lower efficiencies but can still save money on fuel costs due to their lower operating costs. If energy efficiency is a top priority for your industrial processes, it is recommended to consult with an expert to determine the most suitable heater type and configuration.

Regular maintenance is key to ensuring the longevity and safe operation of industrial heaters. Heaters should always comply with safety regulations and standards. Electric heaters are generally considered safer than fuel-fired heaters, as they do not produce emissions or have open flames. However, both types require regular maintenance to prevent malfunctions and potential hazards. It is vital to schedule routine checks and cleaning for your heaters to ensure their optimal performance. Most importantly, always follow the manufacturer's instructions and recommendations for maintenance and safety procedures.

Many manufacturers offer the possibility to custom-design heaters to meet specific industrial needs. This can range from size and shape to heating capacity, energy source, and control options. Customization allows for a more tailored and efficient heating solution that can improve productivity and reduce operating costs in the long run. However, it is crucial to work with reputable manufacturers who have a track record of delivering high-quality customized heaters. In addition, proper installation and regular maintenance are essential for optimal performance and safety.

Industrial heaters are utilized across a wide range of sectors, including oil and gas, chemical processing, food and beverage, automotive, and more. In each industry, heaters have specific applications and requirements, and it is essential to choose the right type of heater for optimal results. For instance, electric heaters are commonly used in food processing due to their precise temperature control, while fuel-fired heaters are more suitable for heating large volumes of air in industrial spaces such as warehouses or factories.

The initial purchase cost of an industrial heater should be weighed against its operating cost and lifespan. Often, a more expensive, energy-efficient heater will cost less in the long run. It is essential to consider factors such as energy source, maintenance requirements, and customization options when determining the overall cost of a heater. Additionally, it is advisable to work with experienced professionals who can help you select the most cost-effective heating solution for your specific industrial needs.

Advanced industrial heaters often feature precise temperature control systems, allowing for uniform heating and improved process reliability. This is crucial in industries where temperature control is critical, such as pharmaceutical and chemical processing. Electric heaters are known for their ability to maintain a constant temperature, making them ideal for sensitive processes. However, advancements in fuel-fired heater technology have also enabled more precise temperature control.

In conclusion, industrial heaters are vital components of numerous manufacturing processes and applications. Understanding the different types of heaters, their energy sources, efficiency, maintenance, customization options, and application areas is crucial for selecting the most suitable heating solution for your specific industrial needs. By considering all these factors, you can ensure optimal performance, energy efficiency, and safety in your industrial operations. So even if you have completed reading this document, remember to keep these key points in mind when choosing an industrial heater for your processes.

Leave your comments

Post comment as a guest