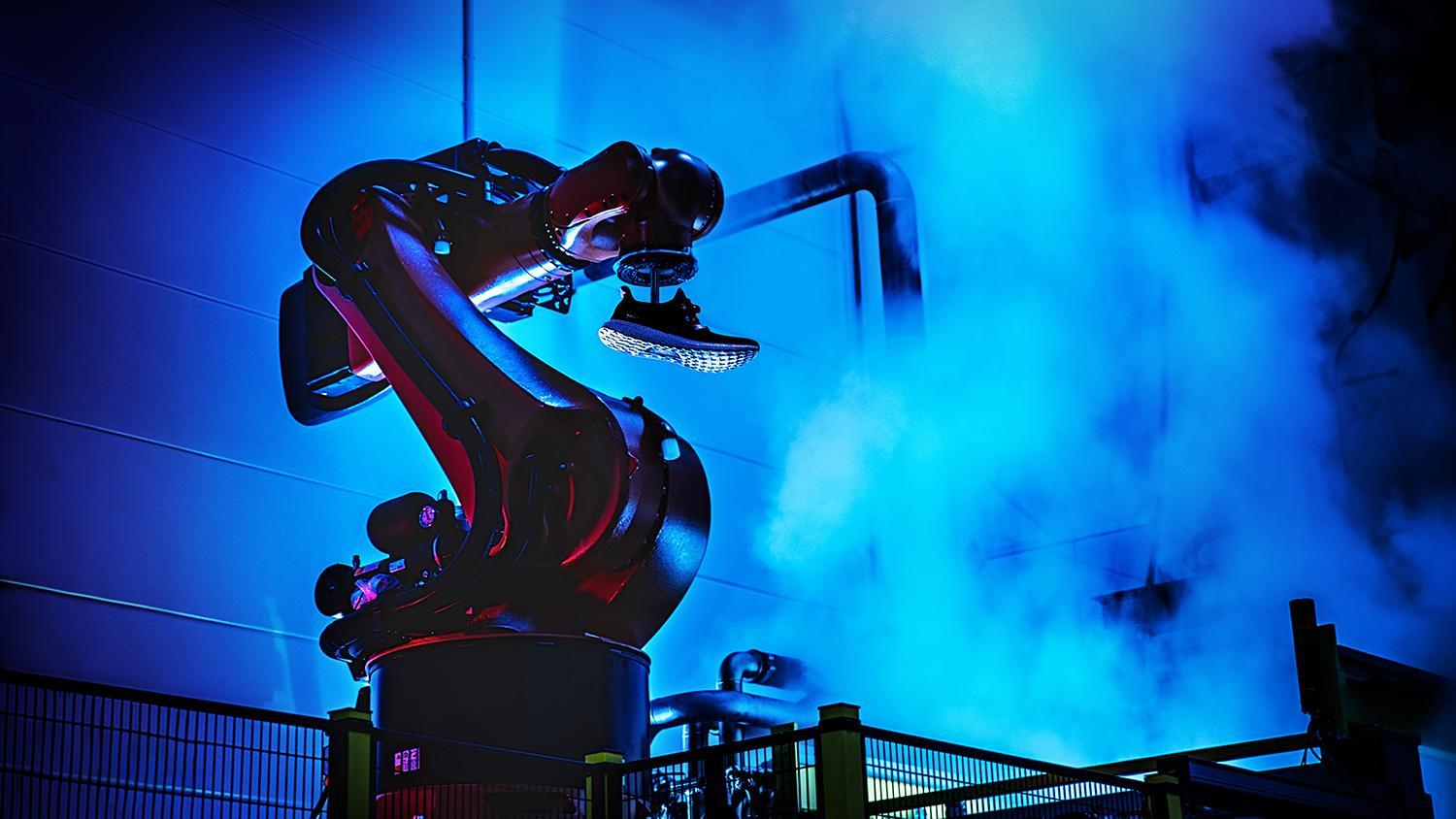

First large scale shoe robot factory unveiled: Adidas is using machines in Germany instead of humans in Asia to make shoes. Adidas, the German maker of sportswear, started marketing its first series of shoes manufactured by robots in Germany since 2017. More than 20 years after Adidas ceased production activities in Germany and moved them to Asia, Adidas unveiled the group’s new prototype “Speedfactory” in Germany. As of 2017, the factory has already begun large-scale production. What's more, Adidas also opened a second Speedfactory in the U.S. last year, followed by more in Western Europe. According to the company, the German and American plants will in the "mid-term" each scale up to producing half a million pair of shoes per year.

Does this pose a threat to Adidas's traditional manufacturing base in China, Indonesia and Vietnam? After all, labor in the region is becoming less cheap these days, and manufacturers are increasingly turning to robots. The current model in the apparel industry is very much based on sourcing products from countries where consumers are typically not based. In the longer term Adidas could even produce the shirts of Germany’s national football team in its home country. The shoes made in Germany would sell at a similar price to those produced in Asia, where Adidas employs around one million workers. Arch-rival Nike is also developing its robot-operated factory.

This development in the shoe area is just the beginning and will be leveraged to the apparel industry as well.

Adidas recently unveiled the first silhouette produced by its Speedfactory facility, the Futurecraft M.F.G. (or Made for Germany)

Put aside for a moment how moving jobs back to a country with high costs gives companies an incentive to automate. There's a bigger issue: After displacing western manufacturing workers, robots are poised to do the same in developing economies, too. It will be hard to re-shore jobs that no longer exist. It took 50 years for the world to install the first million industrial robots. The next million will take only eight. Importantly, much of the recent growth happened in particular in China, which has an aging population and where wages have risen.

A Kingdom of Robots

China is installing more industrial robots than any other country in the world:

In some respects that’s a good thing, of course. Working on a production line is monotonous, and sometimes dangerous. However, building a large manufacturing sector has traditionally been the path emerging economies have taken to raise living standards. Now, robots and other types of automation are a threat to that development model. The United Nations warned two-third of jobs in developing countries are at risk. Add to this the impact of 3D printing, digitalization (includes Artificial Intelligence - AI) and the Internet of Things (IoT).

Many of the jobs done in developing countries can be automated:

Room for Growth - in China

China has a low concentration of robots relative to the size of its industrial workforce:

Why Might it Happen?

Back when the western middle class flourished after World War II, factory automation was expensive. Robots were limited to only a few sectors - mainly the auto industry - and those automatons weren’t that sophisticated. Wages rose thanks to improved productivity, but workers weren’t completely made redundant by the machines. Poorer countries in Asia or Africa probably won't be that lucky. Today's robots are far more capable, are being deployed in a wider range of industries, and are cheaper too. That leaves less room for wages to rise before humans are priced out of the labor market. More low-cost automation also means manufacturing can be re-shored to developed economies.

Cost of an Industrial Robot: €/$ 5 an hour

German robot maker Kuka, acquired last year by China’s Midea, estimates a typical industrial robot costs about 5 euros an hour. Manufacturers spend 50 euros an hour to employ someone in Germany and about 10 euros an hour in China. Rather than seek out an even cheaper source of labor elsewhere - in another emerging Asian economy, say - Chinese manufacturers are choosing to install more robots, especially for more complex tasks. China isn't getting rid of the work, just the workers.

If Robots are the Future of Work, Where do Humans Fit in?

That could be one reason manufacturing employment has already peaked in many emerging economies, and it’s been happening at a quite a low percentage of total employment and at an earlier stage of economic development. Taken together, it's possible robots end up exacerbating inequality in low income countries. We’ll have to deal with the consequences: few manufacturing jobs are coming back to western countries and not many will be created elsewhere and of course the fashion industry will be affected by this development hugely.

Leave your comments

Post comment as a guest