Comments

- No comments found

Elevating construction protocols with enhanced safety practices is crucial for protecting lives and ensuring successful projects.

Almost all companies struggle with doing things “because that’s the way they’ve always done it.” This includes construction companies and their safety protocols.

Someone may have set up the safety standards for your company 25 years ago based on the OSHA standards at that time, and they haven’t been looked at since. If that’s your organization, you’re missing out.

Changes in OSHA guidelines may mean you’re not operating in compliance, and there’s new technology that can make your organization safer and more efficient. Reviewing safety protocols may require some time and investment, but it’s far less than the cost of project disruption, injuries, and liability lawsuits.

Safety protocols play a critical role in mitigating risks and ensuring the well-being of individuals and communities. To enhance your safety protocols, consider the following strategies:

If you haven’t looked at your safety processes in over a decade, it’s definitely time to ensure you’re meeting today’s health and safety protocols.

OSHA breaks safety standards into seven steps, each covering how to manage a different risk. These standards are updated regularly — for example, trenching safety best practices were updated in 2022. Site managers and other construction leaders are responsible for creating a safe environment.

OSHA’s guidelines go beyond preventing falls. There are rules for everything from on-site fuel storage and use to emergency measures to employee training in safety. It’s essential to know today’s standards and build protocols that meet those requirements.

Knowledge is the cornerstone of safety. Regularly train employees and stakeholders on the latest safety procedures, tools, and techniques. Encourage ongoing learning and adaptability to address evolving threats.

Safety protocols should be dynamic and responsive to emerging risks. Conduct regular, in-depth risk assessments to identify potential hazards and vulnerabilities. Adjust protocols accordingly to stay ahead of safety challenges.

A key factor in any safety protocol is clear and efficient communication. Implement and maintain robust communication channels to ensure rapid response in case of an emergency. Make sure all personnel are informed and connected.

Safety equipment is only as effective as its condition. Regularly inspect, maintain, and, when necessary, upgrade safety equipment. The latest technologies and innovations can significantly enhance safety measures.

Practice makes perfect, even in safety. Conduct regular safety drills and simulations to prepare your team for potential incidents. Familiarity with protocols can make all the difference when minutes count.

Safety should be more than a protocol; it should be a way of life. Foster a culture of safety awareness among your workforce. Make it a shared responsibility, with each member actively contributing to a safer environment.

Encourage and facilitate the reporting of safety concerns and near-miss incidents. An open feedback loop allows for the continuous improvement of safety measures based on real-life experiences and observations.

Regulations and industry standards are constantly evolving. Stay informed and ensure your safety protocols comply with the latest requirements. Being proactive in this regard can prevent compliance issues down the road.

Technology offers innovative solutions for safety enhancement. From surveillance systems to data analytics, explore how technology can be integrated to improve monitoring and response capabilities.

No safety protocol is complete without a well-defined emergency response plan. Ensure your plan is detailed, actionable, and regularly practiced. A swift and organized response can minimize the impact of critical situations.

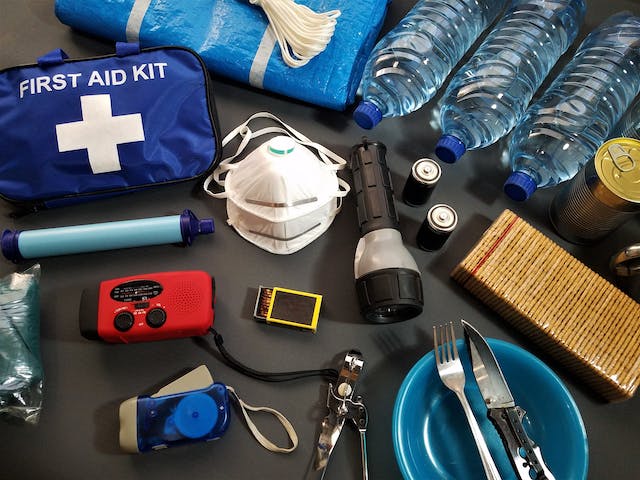

If there’s an injury, the first aid kit nearby can be the difference between quick treatment and a negligence claim against your company. If your organization doesn’t regularly check first aid supplies and other emergency equipment, it’s possible the materials are outdated and even ineffective.

Also, there are new supplies that can help your employees respond quickly and prevent the worsening of an injury. For example, you know you need bandages of various sizes, but you might not know that 70% isopropyl alcohol (IPA) can help disinfect injuries and should also be kept on hand. You can also use IPA to disinfect surfaces, and alcohol can also clean and degrease equipment.

Other essential equipment should be checked and tested regularly, including fire extinguishers, biohazard bags, AED machines, and more.

Don’t let your first aid supplies languish. In an emergency, your employees won’t have what they need, opening you up to liability concerns. Check and restock as needed!

A lot of injuries are attributed to improper training and safety equipment. It can be challenging to offer safety training because the training itself can be dangerous. However, technology like virtual reality (VR) has changed how training is administered, making it far safer and more effective.

Construction sites are full of hazards, and whether you’re training a new employee or refreshing the skills of experienced workers, it’s hard to expose people to challenging situations without risking serious injury. VR training creates a realistic, immersive training environment at a low cost with no risk of injury. This revolutionizes what you can teach your team.

You no longer have to create expensive, dangerous scenarios for training. You also don’t have to expose new employees to 20 hazards on-site when they’re only trained to manage 10 of those. Instead, you can have employees put on a headset and learn how to manage a wide variety of safety scenarios without any actual risk.

Machine learning (ML) is a type of software that can analyze huge amounts of data in a short time and understand the patterns in that data. From those patterns, machine learning solutions allow you to predict when equipment is likely to break down or when something about the job site or work might result in an injury.

Job sites are constantly changing, and site managers can’t be everywhere at once. However, predictive analytics from machine learning software can pinpoint patterns that often result in damage or injury, helping the site manager be in the right place at the right time. The software can also help you optimize maintenance on large machinery, reducing downtime and construction disruptions.

Your company can also use cameras along with AI safety software to observe the worksite and alert workers and managers to unsafe conditions, a potential hit-by, or a violation of safety procedures.

These tools can make your worksite far safer and help you be proactive in preventing incidents, rather than spending your resources on responding to them.

Keeping your team members safe is worth the time and effort it takes — especially since OSHA can inspect your worksite and issue significant fines. Taking the steps we described above allows you to stay in compliance with OSHA’s regulations and can make your worksite more efficient and productive.

AI and machine learning are not tools for tech firms or factories. They can be significantly helpful in detecting safety issues, keeping maintenance on schedule, and more. You can’t afford to do things the way you always have — workers and projects need you to be up-to-date!

Leave your comments

Post comment as a guest