Comments (1)

Reece Villiers

Fantastic read with lots of good basic info!

In every household and working environment, metal plays a crucial role in how people live and work.

From light fixtures and appliances to desks, chairs, and utensils, metal is the stabilizing element that makes nearly all of today's conveniences possible.

Fabrication alludes to any process that shapes, cuts, or otherwise forms a particular material into an end product. Consequently, metal fabrications are considered procedures involving cutting, bending, shaping, welding, or another way of assembling metal material to manufacture end metal products.

For instance, the panels containing each car's frame are made through custom metal fabrication processes, usually performed at a fabrication facility, and later sent to the auto assembly plant.

The fabrication of metals is a beneficial procedure for many businesses and industries worldwide. The fabrication method utilized to create a specific item from metal depends on a broad range of factors, including its final appearance, purpose, and available budget.

Before we dive into the pros and cons that metal fabrications put on the table, it's essential to understand the different types of metal fabrications and how they work.

Metal fabrication involves a broad range of distinct manufacturing processes. As we previously mentioned, selecting a fabrication type or method suited to a given project largely depends on the part's geometry, the end product's intended purpose, materials, and available budget. Standard metal fabrication processes include:

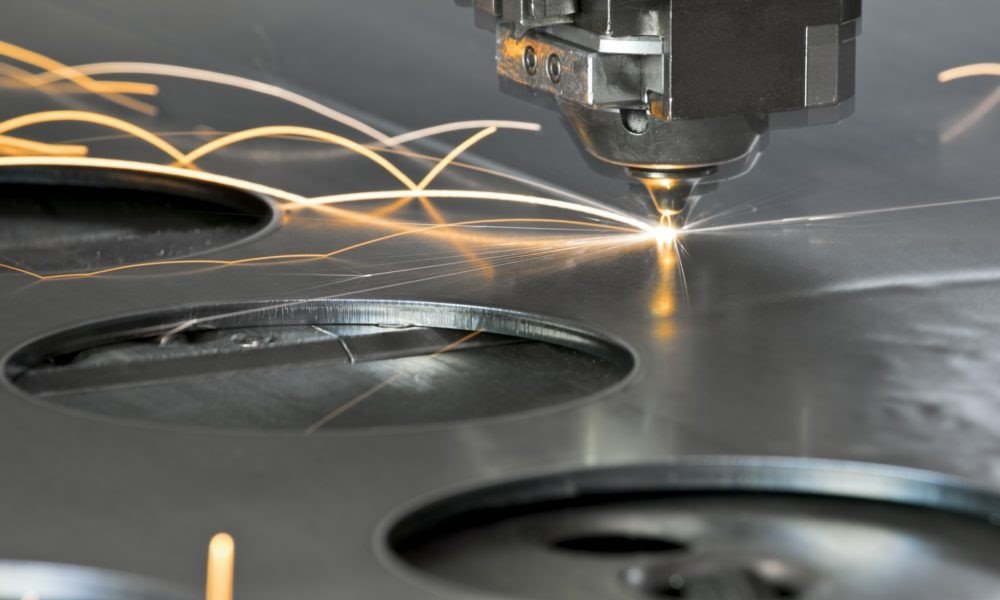

Possibly the most frequently used metal fabrication process is cutting, where huge sheets of metal are split into halves, thirds, or even humbler sections. In many applications, the metal being cut is freshly created and could be cut and shaped into anything in particular.

For other applications, pre-shaped metals like bars, for example, are submitted to cutting. Cuts can be performed with a colossal machinery range, from burn tables to more elaborate and high-tech machinery pieces.

Folding is one of the most intricate metal fabrication types, where the metal surface is manipulated to shape at a certain angle. With specific folding applications, the fabrication's goal is to make the surface fold at a 90-degree angle or something else that's either more or less blunt.

Nonetheless, folding can only be done within facilities equipped with special high-tech equipment because of the complexity of the whole procedure. On many occasions where a fold is required, the more practical alternative is to join two separate metal panels at a selected angle.

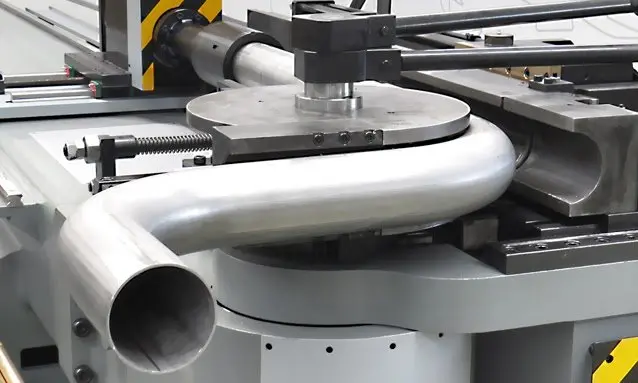

Bending is a well-known metal fabrication and post-fabrication process, highly utilized when forming metal pipes and tubes into usable end products. Metal bending is embraced in nearly all metalworking industry segments, from steel and metal engineering to aerospace and automotive engineering.

Speaking of pipe bending, the fabrication process can be carried out either manually or by computer-controlled pipe bending machines using a hot or cold forming methodology.

Digitally controlled pipe and profile-bending machinery comes especially handy when you need to bend the metal materials at troublesome angles and meet your customers' highest technical and quality requirements.

Photo from Business Archives Blog

As a widely used type of metal fabrication, welding is the process of joining two detached metal parts into one. The components used in the welding procedure could be panels, bars, sheets, or other shapes - as far as the pieces are made out of metal, it doesn’t matter.

The process of welding is feasible through numerous techniques, methods, and tool types. A weld is regularly achieved by applying heat along the points where the two metal parts are meant to be joined.

Casting is one of the oldest metal fabrication types, where molten metal is cast into a mold and is left to solidify into a particular form. Casting is also one of the most flexible metal fabrication methods and is ideal for a broad range of complex shape-making procedures.

In many cases, casting offers a solution to fabrication problems that would alternatively take numerous other methods to solve, such as with assembly pieces that would need shearing, folding, and stamping. The most popular metals regularly employed in this application include iron, steel, copper, gold, silver, and even magnesium.

Other famous types of metal fabrication include punching, shearing, and stamping.

The metal fabrication process largely depends on the family and grade of metal material used to produce a specific piece. Metal fabrication is known to provide the following advantages and benefits:

Even though metal and metal fabrication offer numerous advantages and benefits, like every other creating process come with a set of disadvantages or cons that include:

To sum it up, metal fabrication is an incredibly important process that’s massively employed to create a specific end product from various metal materials. Highly depending on your desired end product’s form, purpose, and your budget, choose a metal fabrication type that suits your needs and complements your work.

Photo from RapidDirect

Fantastic read with lots of good basic info!

Leave your comments

Post comment as a guest