Comments (2)

Stephanie Lane

Artificial intelligence is an essential part of food production.

Luke Williams

Surveillance systems with the ability to detect and track food can provide better hygiene results.

The use of artificial intelligence (AI) in the food industry is already transforming the way food is processed and consumed.

As the technology becomes more capable, it can be used in more advanced applications that can make food production more efficient, safe and profitable.

The food industry has always been at the forefront of adopting emerging technologies for improving the myriad activities involved in the sector. For instance, advances in the field of genetic engineering are leading to the production of crops and food products that are not only healthier for the consumers but also more easily cultivable for the producers. Similarly, the use of blockchain is being considered to improve food supply chain visibility, making supply chains more transparent and trustworthy for both the customers and the supply chain partners. Similarly, the potential of AI in the food industry is being increasingly explored and discussed in recent years. AI, which is already proving is capabilities in fields like manufacturing and commerce, can undoubtedly make an impact in the food industry. It can not only automate routine tasks but also help in proactively managing the food supply chain.

Leading business in the food industry are already adopting artificial intelligence to automate different parts of their operations. Primarily, they are being used in areas where large volumes of data must be processed to solve optimization problems and drive operational excellence. The use of AI in the food industry is also helping food manufacturers to automate routine, repetitive tasks so that they can use their human personnel for more creative, strategic functions. Here are 5 ways artificial intelligence is making an impact on the global food industry:

Supply chains are getting more and more expansive by the day. While the food supply chains of the past only included the few food processing and packaging units owned by a single entity, the modern supply chain is more inclusive. Supply chains in the food industry are expanding to include more and more of the food-making process, from the farms and orchards that produce the basic ingredients to the retail stores and even restaurants. Thus, the food supply chain today includes many different units, controlled by different stakeholders, having different objectives. Managing such supply chains effectively requires constantly monitoring the entire gamut of operations undertaken at each stage. And all of this information must be coordinated and transmitted to the right people at the right time to trigger the right actions. Doing so manually for large supply chains becomes infeasible and disadvantageous. And hence, AI can be used for this purpose.

AI-powered supply chain management systems can be used to constantly monitor and control the activities throughout the supply chain. Using wireless communications and remotely controllable technologies like IoT to connect the food supply chain, which means that all the units of a supply chain are perfectly synchronized with each other. This is vital in the food industry, where most ingredients are perishable and cannot be preserved for long. Thus AI can be used to schedule the ordering process in such a way that perishable goods do not spend too much time in storage, as that may lead to the degradation of the overall food quality.

AI can also be used to control the conditions in which food is transported. Food products or the ingredients to make these products like foodgrains, fruits, meat, dairy, and poultry products are often easily degradable. This means that they must be stored and transported under favorable conditions of humidity and temperature. To ensure that these goods reach the processing facilities in the best of condition, the storage and transit conditions must be constantly monitored and maintained at the optimal level. Using AI integrated with IoT systems can help in automatically controlling the storage and transit conditions. This will ensure that perishables always reach their destination in the ideal state, ensuring a high quality of the end product.

Food processing facilities usually comprise of continuous production processes performed by a series of machines. Any breakdown in such food processing systems can potentially mean stopping the entire operation. Even minor issues in such systems can lead to the stoppage of the entire production process. And stoppages lead to the wastage of labor and time. Hence, it is crucial to maintain all equipment in perfect working condition for as long as possible. And to do so, AI can be used. The use of AI in the food industry has given rise to automated predictive maintenance. AI systems can constantly monitor equipment health and initiate maintenance activities. This can ensure the continuity of operations, maximizing their process efficiency and resource utilization.

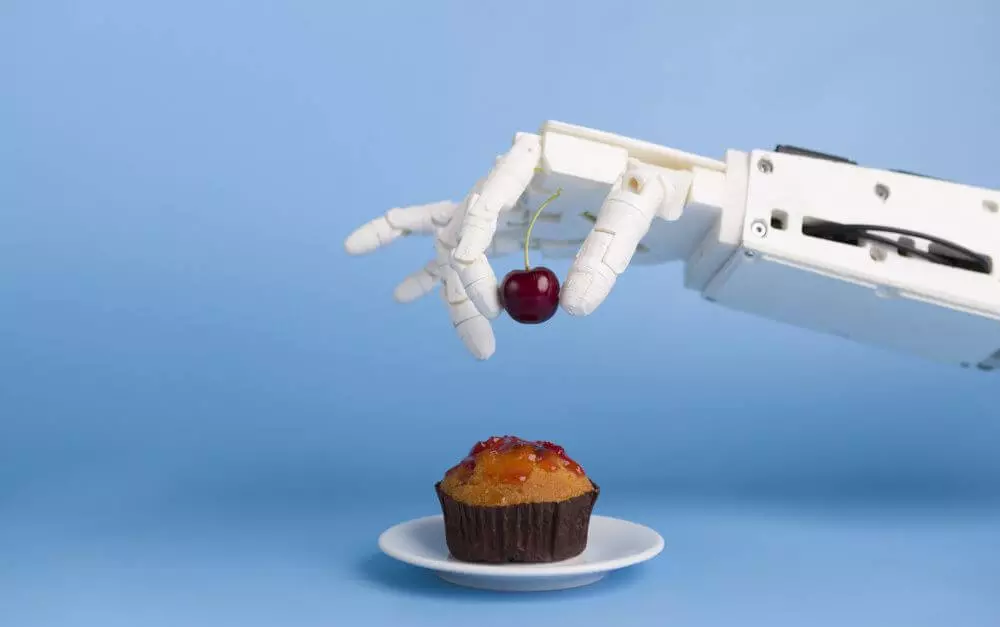

Food processing in many places is not a fully automated affair. It involved human workers for different functions in many food processing and packaging factories. And when humans are involved, regardless of the level of precaution taken, total hygiene cannot be guaranteed all the time. This means that to ensure complete hygiene and high food quality, food processing organizations must automate as much of their processes as possible. They can use robotic equipment powered by AI to mimic the dexterity of human hands of the process requires that. Automating food production can maximize food quality and ensure good safety.

Food delivery is a growing segment of the food industry. And the use of AI is a common enabler for most food delivery organizations. Food delivery services use AI to automate their marketing efforts. AI algorithms study individual customer behaviour on their website to identify their likes and dislikes. They learn each customer's preferences to offer highly targeted food and restaurant suggestions. AI systems also automate the activities involved in the ordering, dispatching, and billing processes to maximize the efficiency in these areas. Using AI, in addition to maximizing efficiency also minimizes human error in these activities which ensures quicker service times and greater customer satisfaction. Food delivery service companies also use AI in customer service. AI-powered chatbots are used by food companies to automatically clear customer queries regarding their orders, resolve minor complaints, and escalate major complaints to the right personnel.

Thus, the transformational role of AI in the food industry is undeniable. However, AI technology, at the current stage, is only in the early phases of adoption despite already proving its worth through different applications. This goes to show how the present day applications of AI are only the tip of the iceberg, as it were. With time, as AI systems become more advanced and accessible, the entire food industry will witness the full extent of AI capabilities.

Artificial intelligence is an essential part of food production.

Surveillance systems with the ability to detect and track food can provide better hygiene results.

Naveen is the Founder and CEO of Allerin, a software solutions provider that delivers innovative and agile solutions that enable to automate, inspire and impress. He is a seasoned professional with more than 20 years of experience, with extensive experience in customizing open source products for cost optimizations of large scale IT deployment. He is currently working on Internet of Things solutions with Big Data Analytics. Naveen completed his programming qualifications in various Indian institutes.

Leave your comments

Post comment as a guest