Comments

- No comments found

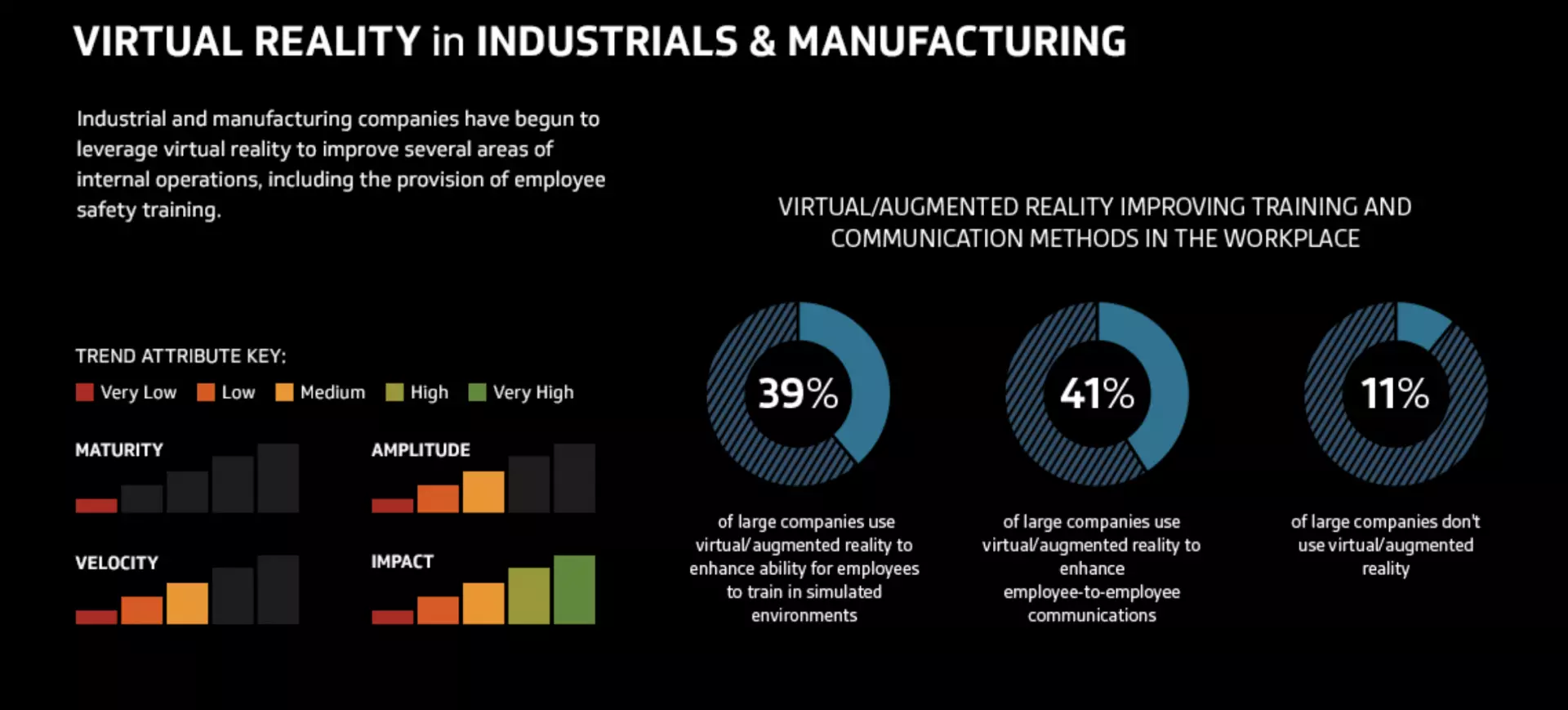

Virtual reality provides exciting opportunities in the industrial automation manufacturing industry.

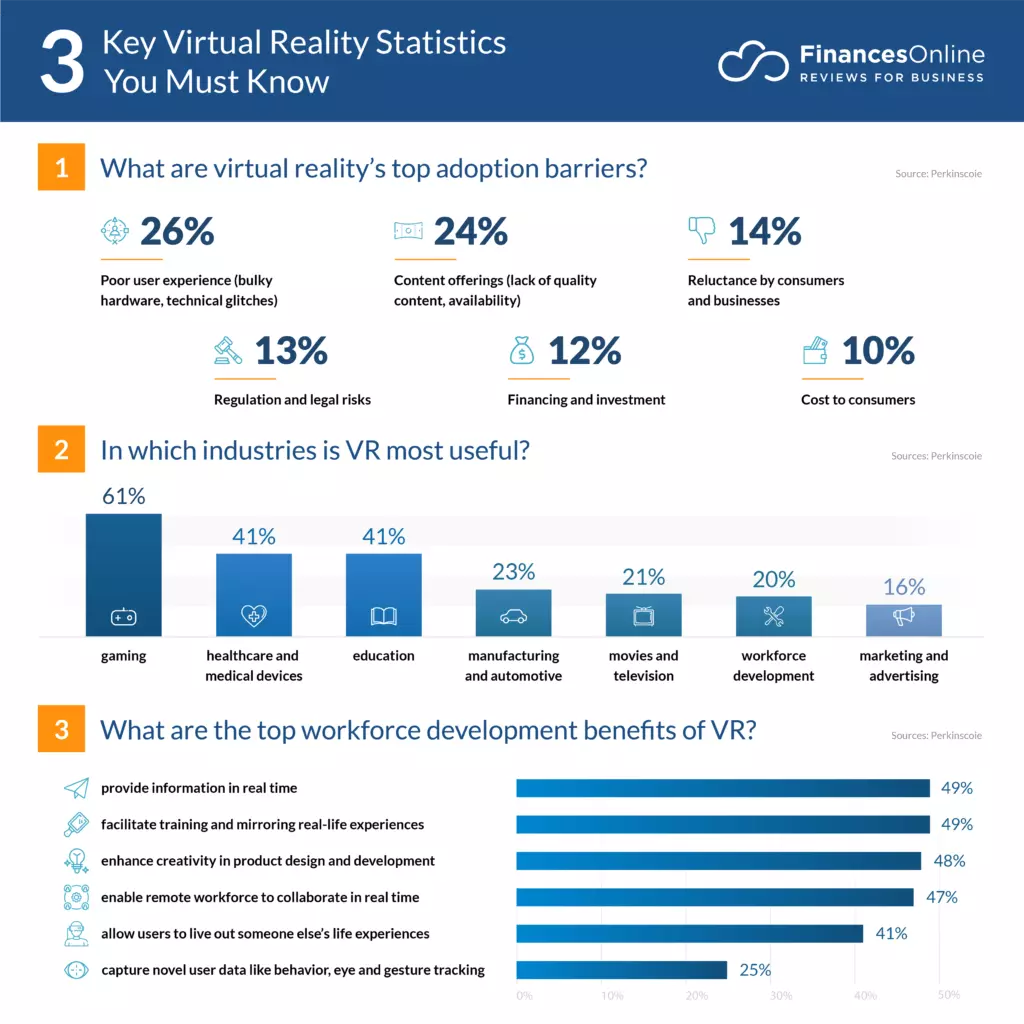

There is a lot of talk right now about the way in which artificial intelligence and automation will impact the jobs market and various different industries.

But don’t forget the impact that virtual reality promises.

Virtual reality has the potential to fundamentally alter the way we work, deliver services, and collaborate. In fact, it could even drastically change – and expand – what we are capable of accomplishing.

In automation, this impact is likely to be felt in a big way. Here are a few ways that this can happen.

Before you can automate the manufacturing process, you first need a design to put to work. This, in turn, requires you to get to work with CAD software in order to create your digital design.

Traditionally, this means using a mouse and keyboard input, or perhaps a stylus. You’ll be using lots of keyboard shortcuts and constantly rotating and zooming in on the item in order to visualize it in a 3D space.

Virtual reality can make this whole process far easier and more tactile – allowing you to physically manipulate the object in front of you and move around it in three dimensions in order to access and assess different parts. Just like in the film Iron Man!

GE is using VR to build assembly line automation.

This also opens up many more possibilities, including collaboration with others based remotely and the ability to view the product to scale as it would appear in real life. You can even try using many products in virtual reality.

In traditional production, you will need to create a prototype product before ordering large batches. This allows you to look for errors and to test that the item looks good from every angle and works well. Prototypes can also be used to find funding and to demonstrate your ideas to investors.

This can, of course, help to improve safety and avoid accidents. Reportedly, the automotive manufacturer Ford has been able to reduce employee injury by 70 percent.

But VR will allow you to much more quickly find flaws in a product by viewing it from different angles, as well as to demonstrate that product to others. By actually seeing the product as though it were there, you will have a much better idea of the way it will work and therefore be able to accelerate steps in the process.

Training with VR will be easier than ever before. You will be able to practice using tools and materials that would otherwise not be available to you, receive training from tutors based thousands of miles away, and make mistakes with no financial or safety repercussions.

Organizations like Nasa use virtual reality to train their engineers to work in zero gravity conditions using limited tools. Programs already exist that are available to the public that can teach CAD skills and even hands-on expertise such as mechanical engineering.

This is an area where AR could also potentially have huge benefits. AR is “augmented reality,” which combines real-world visual information with 3D overlays. AR can help to outline specific parts of a project that need working on, provide visual demonstrations for how to interact with tools, and more.

While VR is still developing rapidly, its huge potential is already being felt in countless industries around the world. Eventually, it will allow people from all over the world to work on projects as though they were standing the same room – interacting with each other and the 3D model in real-time, and using tools and materials that don’t even exist in reality.

Leave your comments

Post comment as a guest